Process Simulation and Bottleneck Identification: Dynamic Mapping of Flow Constraints and Performance Limits

Imagine a factory floor as a vast river system. Water flows smoothly in some stretches, while in others it narrows, slows, or swirls unpredictably. These narrow sections often determine how fast the entire river can move. In business operations, processes behave in a similar way. Work flows through departments, tools, and decisions just like water through a channel. The art of process simulation is like charting this river with sophisticated instruments that reveal hidden bends, congested passages, and turbulence long before they become visible on the surface.

This metaphor helps avoid the usual definitions of a business analyst and instead brings attention to the deeper role of diagnosing flow behaviour rather than simply documenting steps. In many organisations, professionals who have completed business analyst training in bangalore develop a foundation that helps them interpret these complex patterns with clarity.

The Moving Blueprint: Why Dynamic Models are Essential

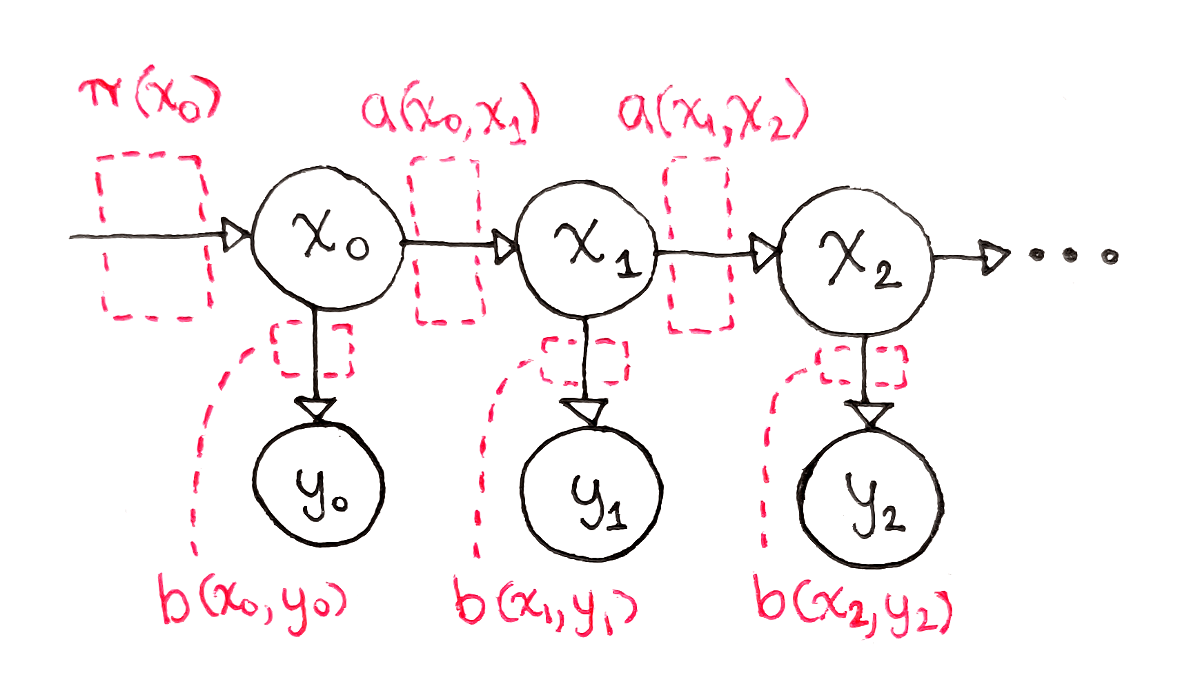

Static diagrams often give the illusion of clarity. They tell the story of a process in still images, showing tasks, hand-offs, and checkpoints. But real operations are animated. People pause, machines halt, approvals queue, and data travels at inconsistent speeds. Dynamic models serve as a moving blueprint that captures these fluctuations in action.

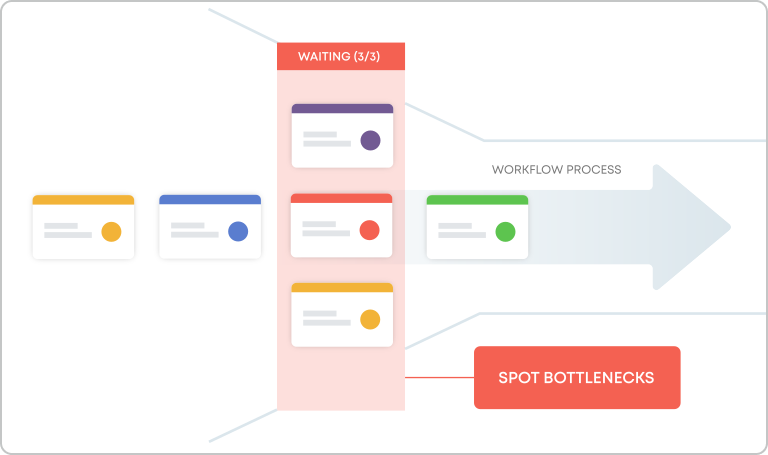

Through simulation, teams can run the same process hundreds of times under different conditions. This helps reveal how demand variations, resource gaps, or environmental shifts can strain the system. Instead of relying on assumptions, organisations gain an evidence-based understanding of how long tasks truly take, where work accumulates, and which decisions create the biggest delays. This animated perspective allows leaders to see beyond the surface, identifying constraints that have been silently shaping throughput for years.

Unmasking Bottlenecks Through Behavioural Storytelling

Processes often hide their bottlenecks behind layers of operational noise. In a metaphorical sense, they behave like characters in a story who appear cooperative but secretly influence the plot. The moment the simulation runs, these characters reveal their true colours. A machine might seem efficient until variability exposes its rigid limits. A manual checkpoint may appear harmless until data shows how it quietly accumulates work during peak periods.

By treating processes as living narratives, simulation reveals:

- The exact points where queues start forming

- The steps are most sensitive to workload increases

- The subtle dependencies that slow everything downstream

- The fragile moments where error rates spike

This approach transforms bottleneck identification into a story of cause and effect. It becomes difficult to ignore the constraints once they are animated, measured, and visualised in a realistic model.

Testing Alternate Worlds Before Making Real-World Changes

Changing a process without simulation is like rerouting a river without studying the terrain. The consequences may be unintended and costly. Simulation empowers organisations to explore dozens of alternate configurations safely. They can increase staffing, shift schedules, automate checkpoints, or redistribute tasks just to see how the process responds.

The advantage lies in controlled experimentation. Businesses can:

- Predict how new policies impact turnaround time

- Test technology upgrades before investing

- Explore the effect of seasonal demand changes

- Compare cost versus speed trade-offs

- Identify the best configuration for peak stability

This sandbox approach is invaluable, especially for decision makers who need to justify operational adjustments with data-backed evidence.

Creating a Common Language for Cross-Functional Alignment

One of the biggest challenges in operational improvement is aligning teams that speak different technical languages. Finance sees cost. Operations see time. Technology sees system load. Human resources sees staffing patterns. Process simulation creates a shared visual and analytical reference point that unites these perspectives.

When teams study the same animated model, communication becomes easier. Misinterpretations fade. Decisions grow sharper. Improvements become collaborative instead of siloed. Professionals trained through structured programs such as business analyst training in bangalore often learn how to bridge these perspectives, ensuring that simulation results translate into practical and sustainable changes across the organisation.

Conclusion

Process simulation is far more than a technical exercise. It is a way of understanding the hidden rhythm of organisational flow. Like a river cartographer mapping currents and obstructions, simulation brings clarity to operations that appear smooth on the surface but struggle beneath it. Bottlenecks cease to be guesses. They become measurable elements that can be predicted, tested, and eliminated with confidence.

As organisations continue to chase efficiency, dynamic modelling provides the compass they need, ensuring that every improvement is grounded in evidence and foresight. By fostering a deeper appreciation of how work truly moves within a system, process simulation transforms the way teams diagnose problems, design solutions, and shape the future of operational excellence.

Post Comment